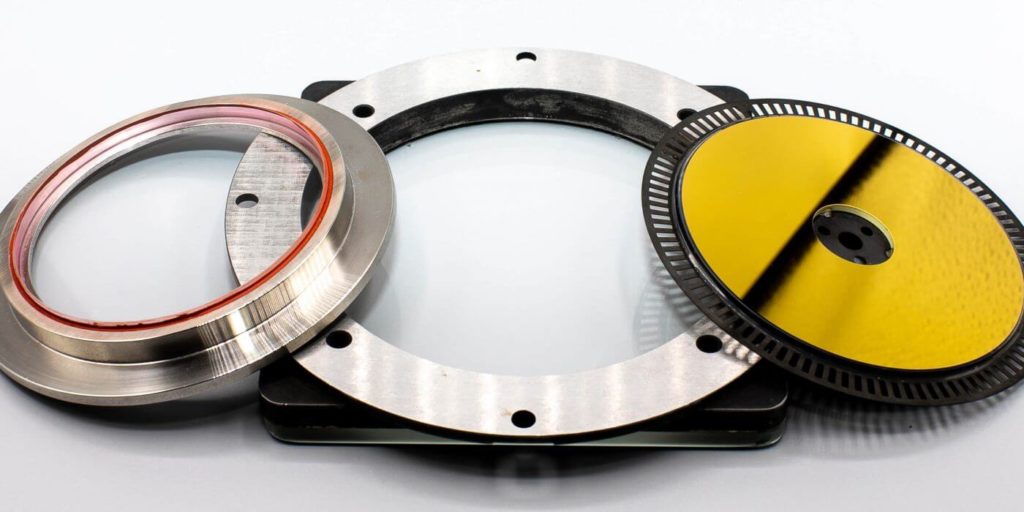

Optical Assembly & Bonding

Sydor Optics offers optical assembly and optical grade bonding of windows, filter stacks and other flat optics to save time and create better integration of optics into larger systems.

DFA/DFM

Our Design for Manufacturing (DFM) team leverages techniques to help provide customers with key design simplifications or changes, adding to the overall manufacturability of the optic. We offer DFM advice to be certain your parts are made to your system requirements, along with cost considerations in mind.

Environmental Control

The two clean rooms offer excellent environmental controls that allow for pristine mounted glass to be integrated into your system. Our process controls ensure stress-free, contamination free and reliable bonded optical assemblies.

About Optical Assembly

Sydor Optics offers multiple optical assembly options for a variety of applications. Our sales team offers unparalleled customer service throughout the process so that your team knows when to accept shipment of finished parts.

Benefits of Optical Assembly at Sydor include:

- Optical-grade bonding of filter stacks and other flat optics

- Stress-free, thermo-set bonding of windows for harsh environments

- UV adhesives for high-volume manufacturing

- Design for Assembly (DFA) / Design for Manufacturing (DFM) for best cost and robust assembly processes

- Low to High volume orders

- 1-Factory software that manages and tracks all aspects of quality control

- Trained staff in the application of Flexible RTV Adhesive Mounting for Glass and Crystal

Flat-surface Bonding Options

Sydor’s flat-surface bonding creates resilient and durable optics. Sydor offers ultra-violet curing for optimum transmitted wave-front error and wedge-free, bubble-free results. Another option, flexible thermo-set adhesives, are ideal for maximum flexibility for high CTE substrates and provide excellent durability.

Our sealed components are able to withstand harsh environments tested at -175 degrees F to 400 degrees F.

Applications that Commonly Use Optical Assembly:

- Bonded windows for harsh environments

- Scopes for defense and special forces usage

- Aerial surveillance windows requiring VIS through IR

- High-powered laser system optics

- Optical filter applications across multiple industries

Excellent Environmental Controls

Sydor Optics provides optimal environmental controls for assembly of your flat optics. Our Class 1,000 cleanroom is complete with temperature and humidity control. Sydor also offers surface roughness testing and durometer measurement.

The Experienced Sydor Assembly Team

The Sydor Assembly Team offers years of experience working with optical and opto-mechanical assemblies, and are experienced in assembly design, allowing us to advise our customers on the best possible approach.