Companies that produce leading edge technologies for military and defense, need high quality windows for their applications. These windows are required to be incorporated into various types of equipment and function in many different environments such as aerospace and harsh regional terrains. Sourcing these windows can be challenging due to the different materials that are required for use in these unique applications.

Sydor Optics has developed advanced processes to manufacture and verify windows made from the many materials that are ideal for use in military and defense applications. The common glass types chosen for windows used in the visible spectrum are Fused Silica and N-BK7 but there any many different materials that are chosen for use in the Infrared (IR) spectrum. In this white paper we present some of the common materials, and the properties that make them ideal for use in these applications.

Silicon

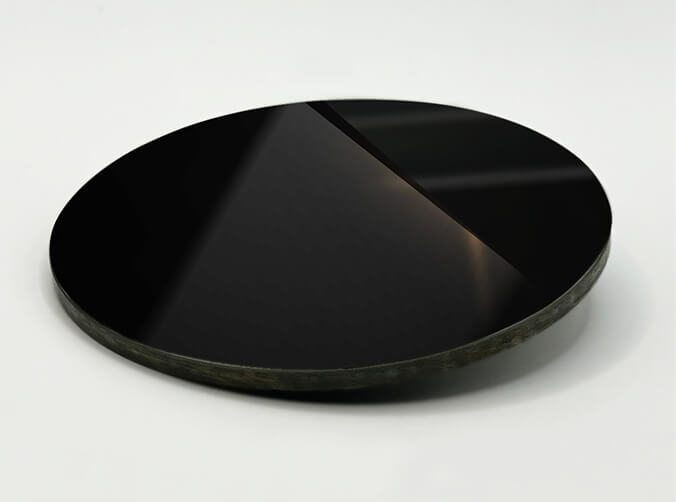

Optical-grade silicon is an infrared (IR) material that is generally specified with 5 to 40 ohm-cm resistivity and usually has a minimum transmission requirement, generally >52% transmission in the range of 2 ‐ 8μm. Since silicon is a crystal, it is available in both monocrystalline and polycrystalline structures, with monocrystalline being the most common. Below are some defining characteristics of using silicon:

- Cubic in nature and will not exhibit birefringence.

- High environmental durability.

- Silicon is lower in density making it ideal for weight-sensitive applications when compared to other popular IR materials such as germanium and zinc selenide.

- Thermal stability.

- More cost-effective for mid-wave applications than other IR materials.

Sydor Optics has well-defined double-side, single-side, and CNC machining processes for manufacturing silicon windows, flats, and wedges. With our 3.39µm interferometer, we have the capability to measure windows in transmission up to 14” in size.

Germanium

Germanium is another popular IR material, and it requires lower resistivity than silicon, generally <5 ohm-cm, but usually has more detailed transmission specifications that cover multiple wavelength ranges from 2.5μm to around 12μm. Listed below are some defining characteristics for choosing germanium:

- Highest refractive index and lowest optical dispersion of commonly available IR-transmitting materials.

- Germanium is relatively hard with high-density making it ideal for IR applications requiring rugged optics.

- Generally, an anti-reflection coating is recommended on germanium windows for sufficient transmission in the region of interest.

- Subject to decreases in transmission as temperature increases, therefore, it must be used at temperatures below 100°C.

Sapphire

Sapphire is a crystal that has very desirable optical characteristics for wear/corrosion resistance and UV/Visible/IR wavelength performance. These properties make sapphire an ideal material for aerospace, high energy lasers, and many other optical applications. While the material can be supplied in different crystal orientations; C-plane, A-plane, R-plane, and M-plane, our processes have been developed around C-plane sapphire. Sydor Optics has processed sapphire windows, wedges, and wafers with processes that have been developed through engineering trials and perfected by our optical technicians.

Zinc Sulfide/Selenide

Zinc Sulfide (ZnS) and Zinc Selenide (ZnSe) are materials that are useful in IR applications. With high spectral transmission from near-infrared (NIR) to long-wave infrared (LWIR), these materials are ideally suited for thermal imaging equipment, specifically in defense and military applications. Multispectral Zinc Sulfide (MS ZnS) or Cleartran® is a modified version of standard ZnS that allows it to transmit in the visible range and increase the functionality in the bulk material. Sydor Optics has developed single and double-sided processes for these materials based on our customers’ requirements and has delivered windows and wedges for high-value applications.

We have developed processes that allow us to double-side or single-side lap and polish these windows to the desired specifications. The process chosen will depend on at minimum the following.

- Size and thickness of the finished window.

- Transmitted wavefront error and/or surface flatness specification.

- Parallel or wedged surfaces.

- Quantity of windows ordered.

Production Capabilities for Military and Defense Window Solutions

Sydor Optics has optimized each process to achieve the best possible flatness, transmitted wavefront error, surface roughness, and surface quality. This allows our team to process these materials in the best possible batch size to meet prototype and volume demands.

Sydor Optics possesses state-of-the-art equipment, supported by an experienced team of operators, to shape windows that need to fit into the frames and turrets that will be used in the end-use application. From applying special flats, angles, or other features, our dedicated and knowledgeable team of CNC programmers/operators can manufacture these optics. Our machines and tooling allow us to shape these windows efficiently with high quality and precision. We have optimized our processes to enable shaping to be either at the beginning or the end of the manufacturing process. It is also important to have the ability to verify the dimensional characteristics of the window and this requires a CMM (Coordinate Measuring Machine) or similar instrument.

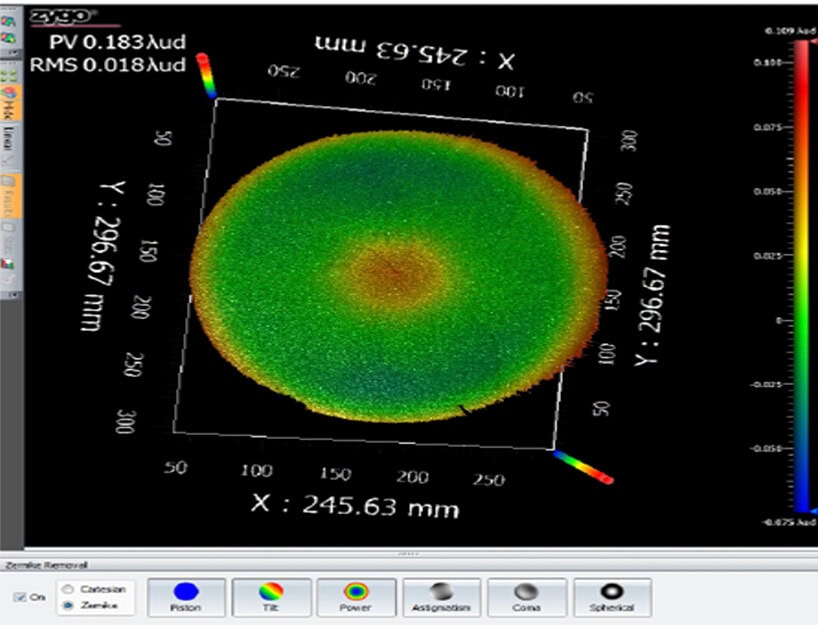

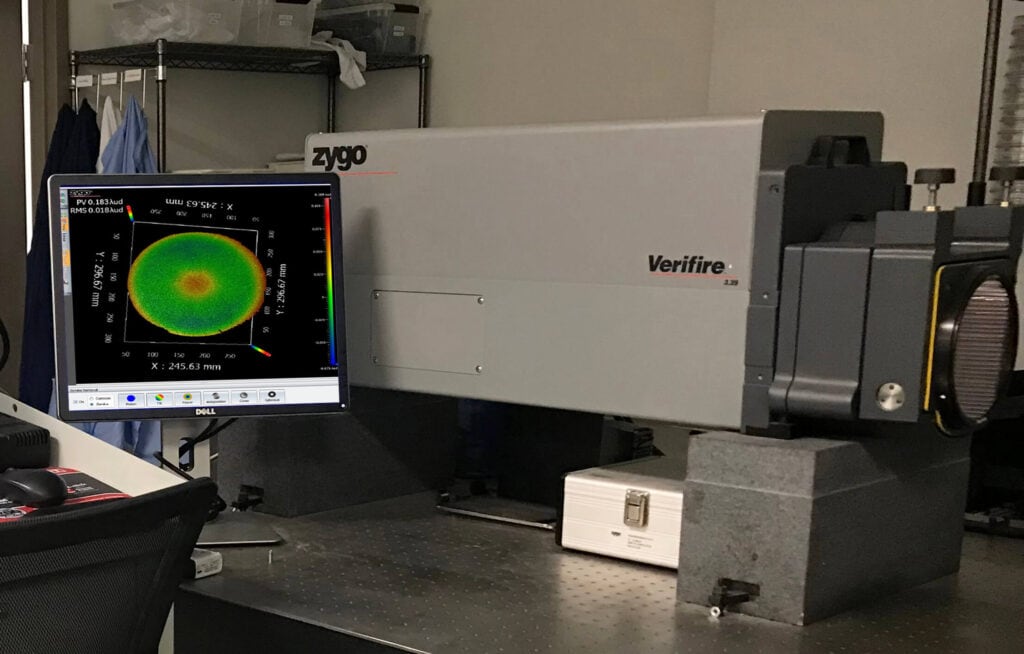

The metrology needed to verify these optics is extremely important to confirm that the optics function in the manner intended by the optical designer. An interferometer that can measure transmitted wavefront in the infrared wavelengths is an imerative step in the verification process and a differentiator in Sydor Optics capabilities. We possess a 6” 3.39µm Zygo Verifire Interferometer equipped with a stitching stage that allows for the evaluation of optics up to 14” in diameter or diagonal. See Figure 1 as an example of a transmitted wavefront measurement from a 10” silicon window.

Most windows will require a coating that enables the optic to function over a specific wavelength range and within varying environmental conditions. To make an optic ready for these coatings, surface preparation and cleanliness are extremely important for the function of the assembled system. Standard optical cleaning and/or ultrasonics with the proper chemistry can assist in providing a very clean surface for the coating to properly adhere to the optic. Sydor Optics provides extremely clean optics, that when coupled with surface contact-free packaging, will be able to be loaded into the coating tools. We also can design and manufacture Pet-G packages with durable formability that will protect the window throughout every step in the process.

RELATED CONTENT

SYDOR OPTICS TO SUPPORT L3HARRIS DOD VAMPIRE CONTRACT FOR UKRAINIAN SECURITY DEFENSE

If you are looking for Infrared optics, Sydor Optics has over 60 years of experience and the validation of long-term relationships in supplying IR windows to major contractors in military and defense.

Please contact one of our dedicated account managers for your next project.