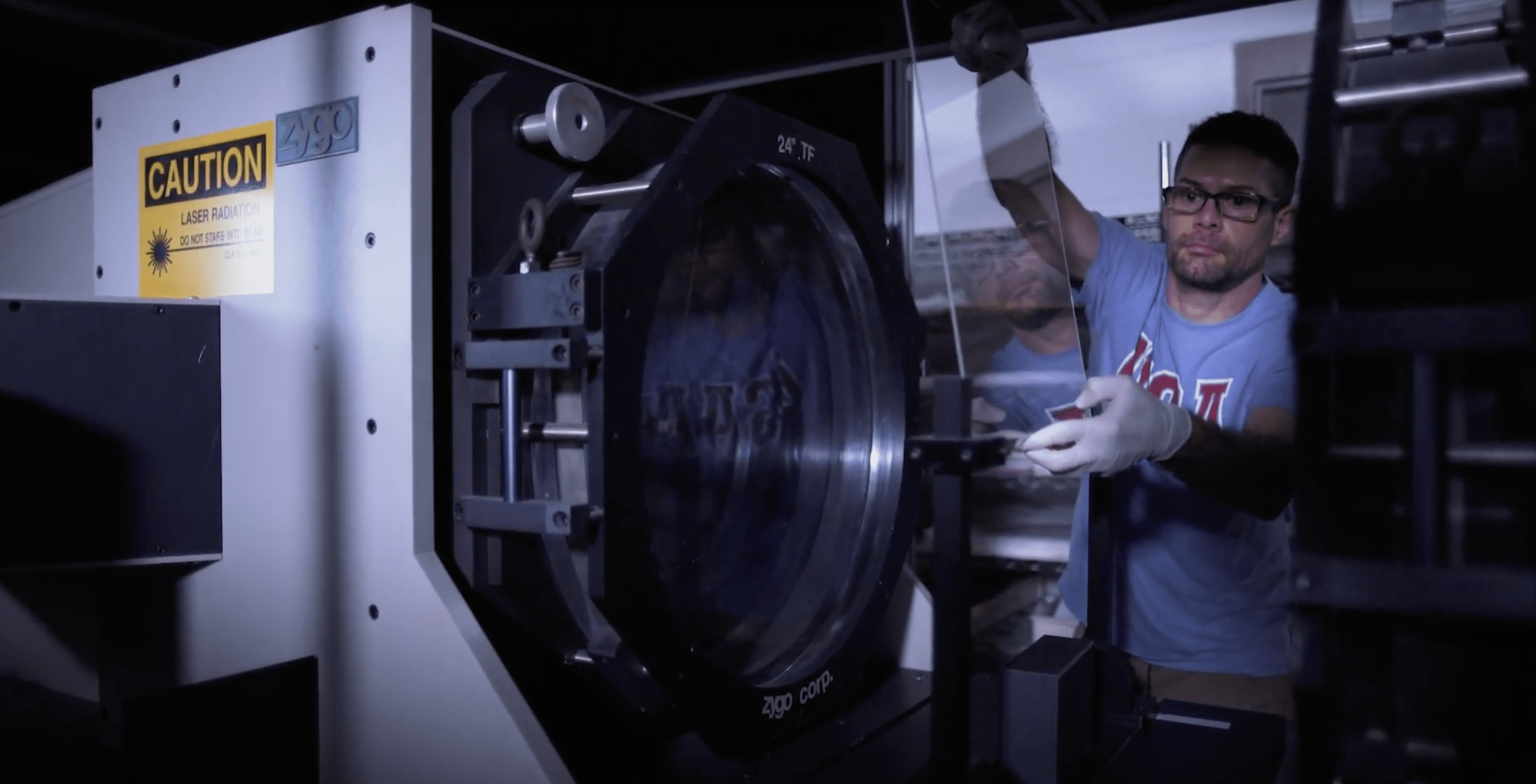

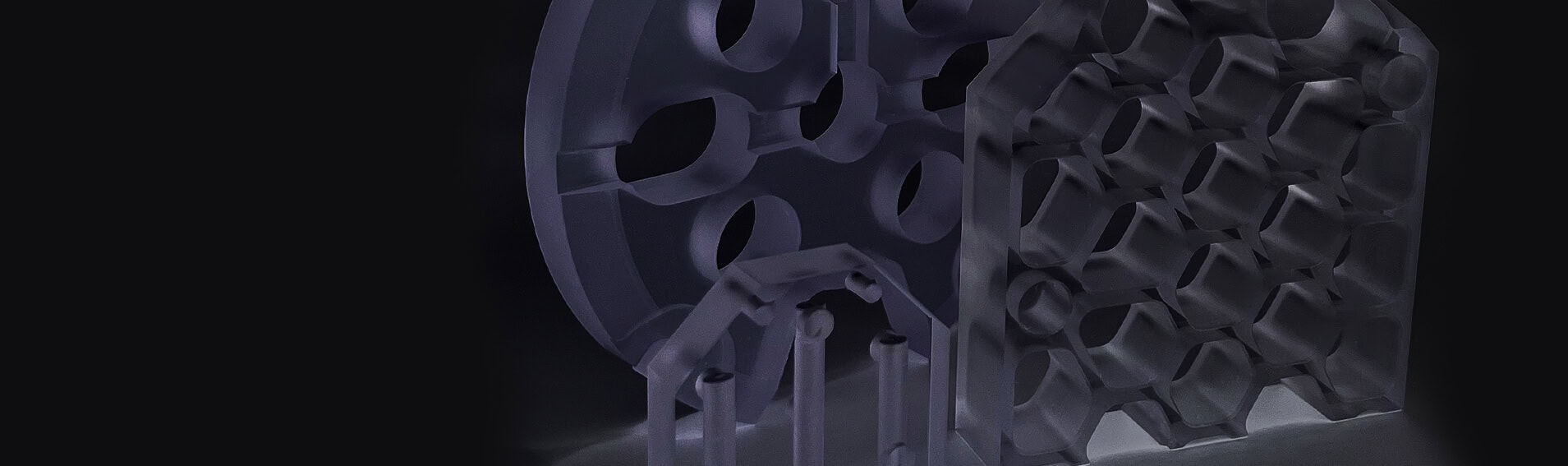

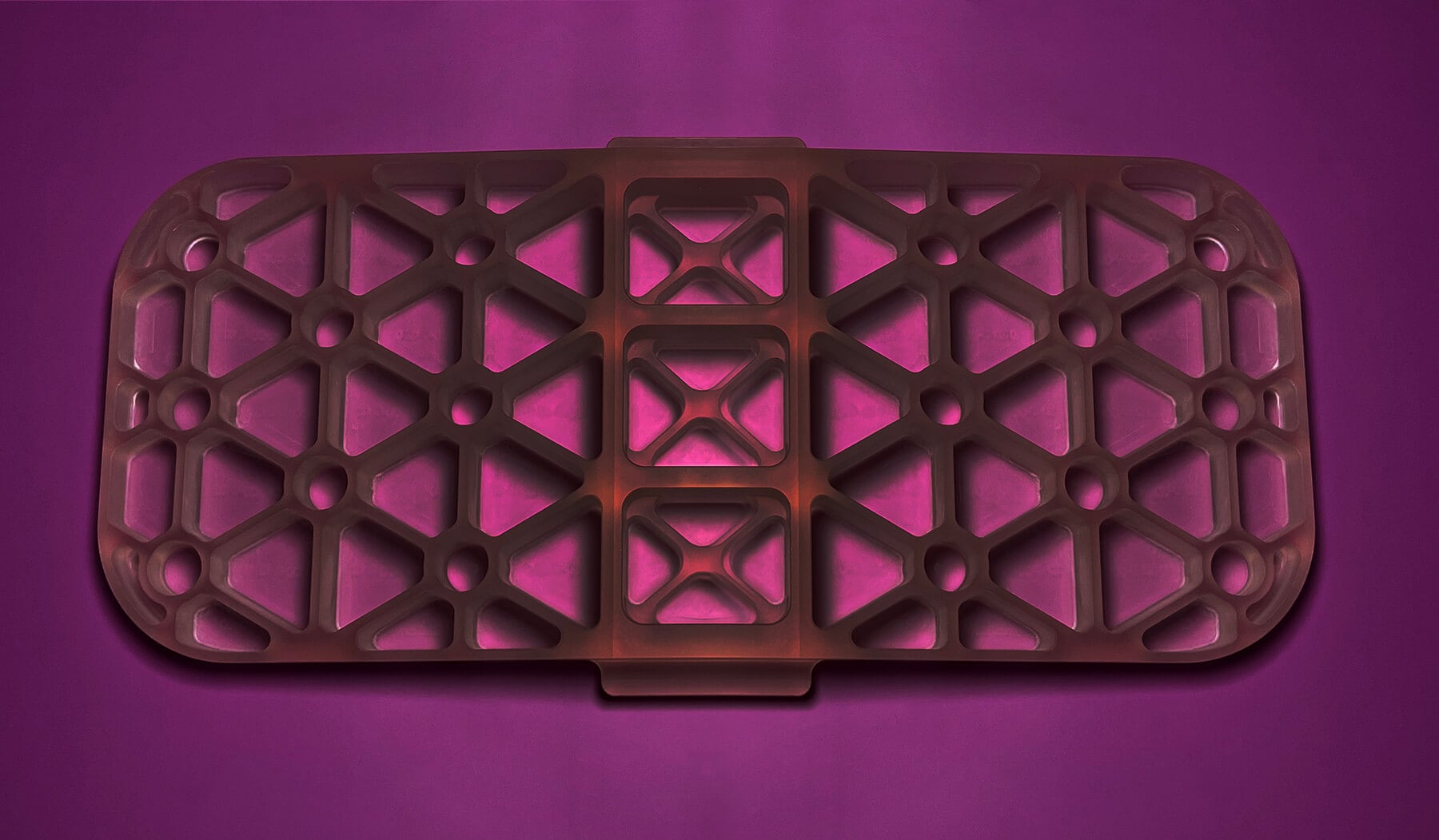

Sydor by the Numbers. A Quick Look at Our Stats.

We’re excited to share some standout statistics showcasing our company’s capabilities and the incredible team behind our success! A tribute and thanks to all employees, our valued clients and suppliers for making these achievements possible. Here’s to continuing to push boundaries and deliver outstanding results together!